Share

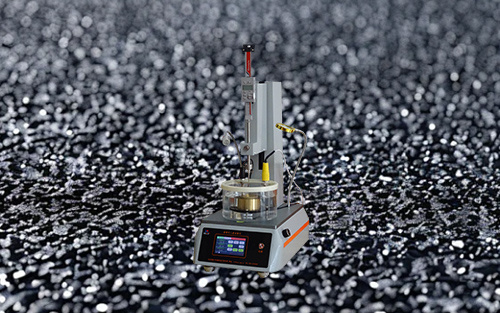

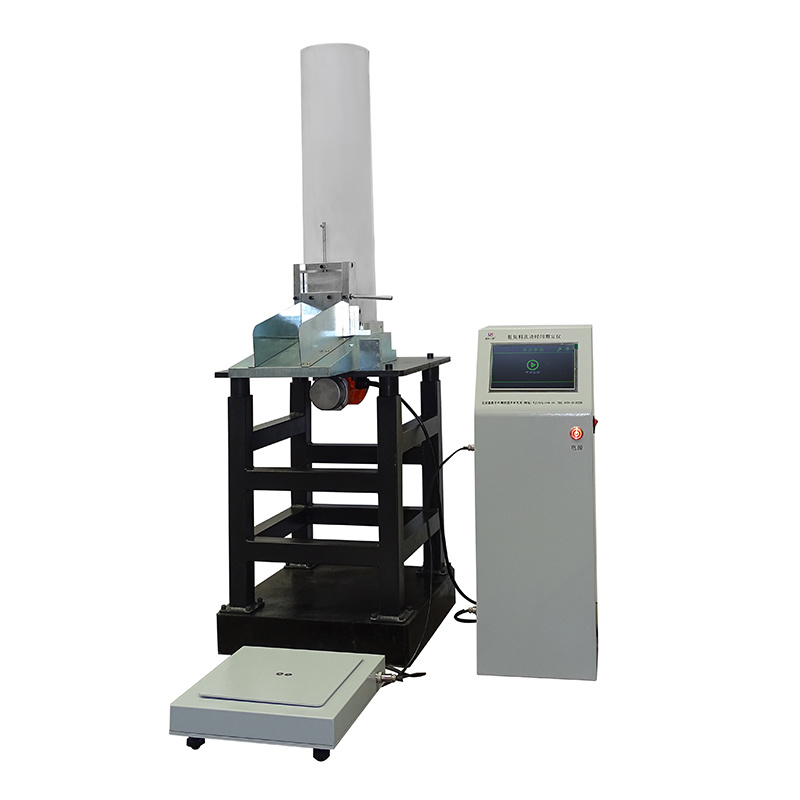

LHZJ-0985D Shear Strength Tester for Bonding Layer

Still decided? Get the samples first,Contact us!

Product classification

- Description

-

This instrument is suitable for determining and evaluating the interlayer shear strength test between two different materials such as bridge decks and others for surface treatments, sealing layers, adhesive layers, penetrating layers, and waterproof layers, etc., with asphalt layers and cement concrete layers, highway asphalt pavement projects, and concrete bridge deck asphalt paving projects. It can also determine the direct shear strength or inclined shear strength of the structure layer-adhesive layer-structure layer.

This instrument is a kind of automatic data acquisition shear force and deformation displacement developed using digital sensor technology. Shear force accuracy 1N. Automatically displays the test peak value, making the reading more accurate and intuitive.

Instrument Structure and Characteristics

1. The LCD data acquisition instrument automatically acquires, saves, and displays shear force and displacement, and prints load data, saving 70 sets of data.

2. The loading speed is uniform and stable.

3. The shear plate is easy and quick to install.

Specification Parameters

Maximum Rated Load of the Instrument 10KN Resolution: 1N Displacement Range 1mm-30mm Resolution 0.01mm Maximum Shear Movement Distance 100mm Shear Loading Speed 0-50mm/min . Adjustable Data Sampling Rate Dynamic 100-5000SPS Power Input 220V±10% 50HZ External Dimensions 30cm x70cm x90cm Overall Weight 150kg Main Characteristics

1. The entire test is automatically controlled by the instrument, automatically tested, eliminating various human errors.

2. It has an overpressure automatic protection function. The instrument automatically stops pressurization and will not be damaged by overpressure.

3. The test peak value and deformation can be printed.

4. The loading and unloading of the instrument are automatically controlled by the instrument.

5. The display uses a special chip, eliminating the display flicker phenomenon during the test.

6. The date and time are added when printing.

Test Methods and Procedures

1. Preparation Work

(1) Before conducting the on-site bonding strength test, the completed surface treatment, sealing layer, adhesive layer, penetrating layer, and waterproof layer materials should be fully cured.

(2) Based on the on-site conditions, randomly select test points and mark them on site.

(3) Use a core drill to take core samples on site. It is necessary to drill through the underlying layer to obtain a complete core sample, generally with a diameter of 150mm±2mm or 100mm±2mm; the sides of the core sample need to be smooth and flat. Three core samples need to be taken at each location, with a distance of no less than 100mm between each core drilling point and a total distance of no more than 1m.

(4) For core samples of the structure layer-adhesive layer-structure layer, the upper structure layer thickness should not be less than 20mm, and the lower layer thickness should not be less than 50mm. When the sample thickness is insufficient, an extended test mold can be used, and the insufficient height end can be bonded to the sample using an adhesive.

For the adhesive layer-structure layer, such as evaluating the interlayer bonding strength of surface treatment, sealing layer, penetrating layer, waterproof layer, and ultra-thin wear layer with the underlying layer, an extended test mold is also needed.

Before bonding, the surface of the sample needs to be cleaned, dried, and adhesive applied, etc., as before.

(5) Place the samples together in a constant temperature box at 20℃±1℃ for 4 hours before proceeding to the next step. Other temperatures can also be selected, and they should be noted in the report.

2. Test Steps

(1) Select the appropriate shear ring, remove the upper pressure head and shear ring, place the sample on the lower shear ring, and then put in the upper pressure head and upper shear ring. The diameter of the shear ring should be controlled within the range of 0~+2mm of the sample diameter. Adjust the sample position so that the adhesive layer is located between the vertical distance of the upper and lower shear rings, and the vertical distance between the upper and lower shear rings should be less than 5mm. At the same time, adjust the upper shear ring so that the upper shear ring is just in contact with the sample surface.

(2) Fasten the sample and tighten the support components.

(3) Start the press and begin to pressurize the upper and lower pressure heads. The loading speed is 0-50mm/min±2mm/min.

(4) When the pressure reaches the peak value, stop the test, record the maximum pressure value and the corresponding displacement, the pressure value is accurate to 0.1KN, and the displacement is accurate to 0.1mm, and give the displacement-load curve. The time from taking the sample out of the temperature control box to completing the test should not exceed 2 minutes.

(5) Observe and record the fracture surface in detail.

Precautions

1. When performing the direct shear test of the adhesive layer, the loading part must be controlled by the instrument, and manual forced loading or manual starting of the motor loading is not allowed, otherwise, overloading may damage the instrument.

2. If the power grid interference is large or the voltage is unstable, a clean power supply, UPS, or AC voltage regulator should be used.

3. The power cord and the loading part control line cannot be stressed.

4. The instrument must be well grounded.

5. The instrument should not share a power outlet with high-power electrical appliances.

6. The instrument should be placed in a cool and dry place.

7. When using the instrument, care should be taken to prevent dust from entering the printer or instrument. When not in use, place it in the packaging box.

8. Please do not open or repair the instrument without authorization to avoid accidents or further damage.

ingenuity quality

Factory direct sales

Support customization

a lot of in stock

Quality Assurance

complete specifications

After-sales worry-free

Factory Scene

Production Scenarios

LHZJ-0985D Shear Strength Tester for Bonding Layer

Still decided? Get the samples first,Contact us!

Product classification

Shipping video

Shipping photos

Shipping scenarios

Shipping

INQUIRY

Note: Please leave your contact number or E-mail address, our professionals will contact you as soon as possible!

Related Products

LHCL-0985E Adhesion Layer Tensile Tester

LHLS-0985A Bonding Layer Dedicated Pull-out Tester

LHLDY-0362 Coarse Aggregate Flow Time Tester

LHSL-326E Expansion Joint Rubber Seal Strip Clamping Performance Testing Machine