Share

LHDZ-105 Laser Road Surface Smoothness and Rut Depth Detection System

Still decided? Get the samples first,Contact us!

Product classification

Keywords

- Description

-

Overview

This device can quickly, accurately, and real-timely detect and calculate indicators such as the International Roughness Index (IRI), Structural Depth (SMTD), Rut Depth (RD), Bump (PB), Wear Index (PW1), Riding Quality Index (RQI), Observation Score (RN), test speed, and driving distance of various levels of highway pavement. It can provide comprehensive and efficient data support for completion acceptance, preventive maintenance, and pavement management systems (CPMS).

Performance Characteristics

1. The data acquisition and analysis software has a full Chinese interface. During the test, it can real-timely acquire, display, and store data on indicators such as the International Roughness Index (IRI), Structural Depth (SMTD), Rut Depth (RD), Bump (PB), Wear Index (PWI), Riding Quality Index (RQI), Observation Score (RN), test speed, and driving distance.

2. Core components are all original imports.

3. The system adopts an integrated modular design, making subsequent maintenance and upgrades quick, convenient, and simple.

4. A portable laptop computer is used for data acquisition.

5. The detected data can be directly imported into the CPMS pavement management system.

6. The detection technical indicators conform to national pavement acceptance and maintenance standards: "Standard for Quality Inspection and Evaluation of Highway Engineering" (JTGF80/1-2017), "Standard for Highway Technical Condition Assessment" (JTG 5210-2018), "Highway Subgrade and Pavement Field Testing Procedures" (JTG3450-2019); conforming to the Ministry of Transport's "Automated Detection Procedures for Highway Pavement Technical Conditions" (JTG/T E61-2014), "Vehicle-mounted Laser Pavement Levelness Instrument" (JT/T676-2009), "Vehicle-mounted Laser Pavement Structural Depth Instrument" (JT/T840-2012), and "Vehicle-mounted Laser Pavement Rutting Instrument" (JT/T6772009) industry standards.System Composition

• Data Acquisition Computer

• Data Acquisition Host System

• High-precision Laser Sensor (including: 13 laser sensors)

• High-precision Accelerometer (including: 2 accelerometers)

• Vehicle Inverter Power Supply

• Data and Power Connection Cables

• Data Acquisition and Processing Software

• Equipment Mounting Bracket

• DMI Distance Measurement SystemTechnical Index

① Basic Parameters

Vertical Distance Measurement Indicated Error ±0.5mm Longitudinal Distance Sensor Error ≤0.05% Detection Speed Influence Error ≤5% IRI Measurement Repeatability ≤5% IRI Measurement Error ≤15% IRI Measurement Range 0~15m/km Test Speed Levelness 20~120km/h Structural Depth Indicated Error ±15% Structural Depth Measurement Repeatability ≤10% Structural Depth Measurement Range 0~3mm Test Speed Structural Depth 0~120km/h Rut Measurement Range 0~100mm Number of Cross-sectional Sampling Points ≥13 Effective Detection Width of Cross Section ≥3.5m Rut Depth Measurement Repeatability ≤5% Test Speed Rut Depth 0~120km/h ② Software:

Test Results: International Roughness Index (IRI), Structural Depth (SMTD), Rut Depth (RD), Bump (PB), Wear Index (PWI), Riding Quality Index (RQI), Observation Score (RN), test speed, and driving distance.

③ Operating Environment:

1. Ambient Temperature: -25~60°C

2. Ambient Humidity: No more than 85%

④ Mounting Bracket:

1. Installation Method: Fixed to the front of the vehicle

2. Material: Stainless steel mounting bracket

ingenuity quality

Factory direct sales

Support customization

a lot of in stock

Quality Assurance

complete specifications

After-sales worry-free

Factory Scene

Production Scenarios

LHDZ-105 Laser Road Surface Smoothness and Rut Depth Detection System

Still decided? Get the samples first,Contact us!

Product classification

Shipping video

Shipping photos

Shipping scenarios

Shipping

INQUIRY

Note: Please leave your contact number or E-mail address, our professionals will contact you as soon as possible!

Related Products

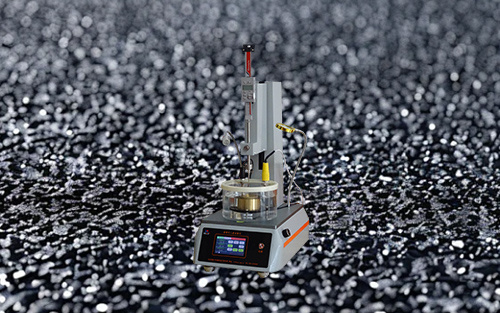

LHCL-0985E Adhesion Layer Tensile Tester

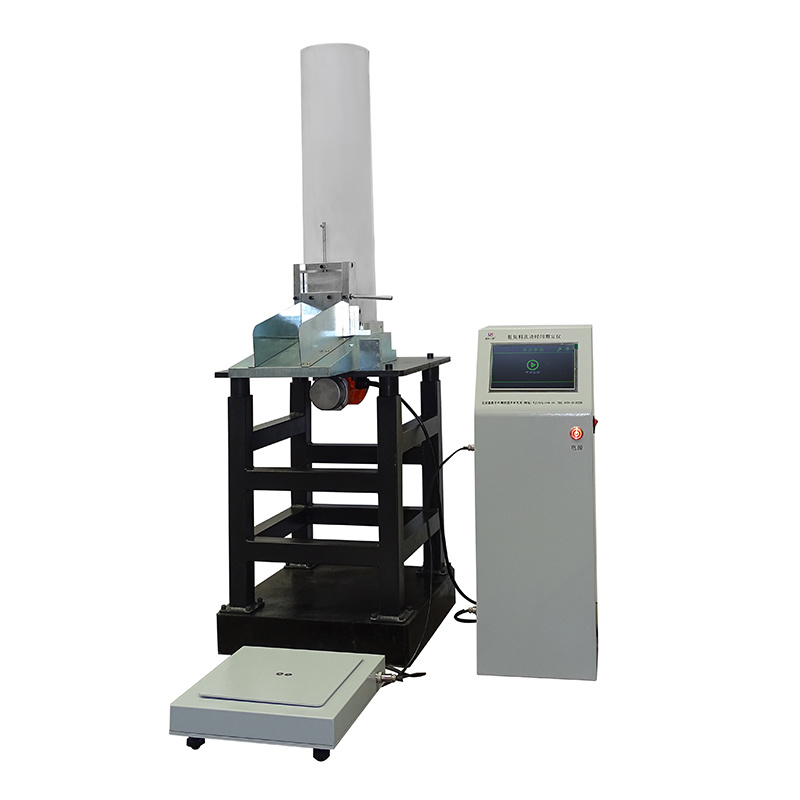

LHLS-0985A Bonding Layer Dedicated Pull-out Tester

LHLDY-0362 Coarse Aggregate Flow Time Tester

LHSL-326E Expansion Joint Rubber Seal Strip Clamping Performance Testing Machine