Share

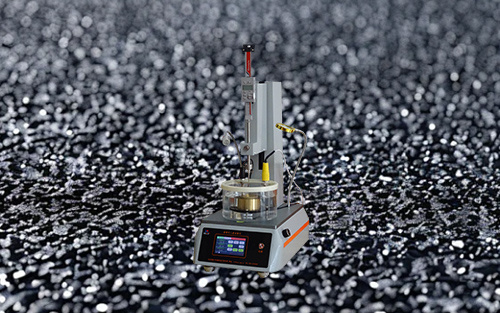

LHCQ-533A pneumatic screen

Still decided? Get the samples first,Contact us!

Product classification

Keywords

- Description

-

This instrument is designed and manufactured in accordance with the relevant requirements of the Ministry of Transport's "Fiber Stabilizer for Asphalt Pavement." It is suitable for fibers of certain specifications in flocculent cellulose fibers and flocculent mineral fibers. It is sieved through an air-jet sieve to calculate the fiber's passing rate and other technical indices, thus ensuring the quality of fibers used in asphalt mixtures.

In addition to being used for fiber sieving as required by "Fiber Stabilizer for Asphalt Pavement," this instrument can also be used for dry powders that cannot be analyzed by conventional sieve analysis, such as: light powders, powders that easily generate static electricity, and powders whose particles easily agglomerate. Therefore, this instrument can also be widely used for sieving the following powders: pharmaceuticals, flour, seasonings, chemical powder, cement, graphite, fly ash, coatings, clay powder, resin, rubber, plastics, etc.

etc., is a multi-purpose air-jet sieve analyzer.

Main Technical Features

1. This instrument is mainly used for sieving fibers used in asphalt mixtures. Different air-jet sieves can also be selected according to needs for air-jet sieving of various materials, achieving the purpose of one machine for multiple uses.

2. It adopts world-leading opening sieve technology, effectively preventing near-sieve particles from blocking the sieve mesh and solving the problems of sieving caused by particle suspension, particle agglomeration, and electrostatic properties.

3. It adopts stable negative pressure and air-jet airflow sieving technology, and is used with a 200mm diameter standard sieve for timed sieving and measurement of particle size distribution, with accurate results. It has a delicate appearance and is lightweight.

4. It adopts color touch screen display and control technology, and all sieving operations are completed on the touch screen.

5. It is equipped with a high-quality vacuum cleaner to provide the stable negative pressure required for sieving

Main Technical Parameters and Indices

Air-jet Sieve Sieve mesh: 0.15mm, Specification: Φ 200mm × Height 48mm standard sieve Sieve Mouth Speed Fixed 35 rpm Sieve Mouth Gap 2 mm Sieving Range 20 um~5,000 um Timing Range 0~99 minutes 59 seconds Maximum Sample Loading 2000g Operation Control LCD color screen display, touch screen click for precise control of sieving operation Working Power Supply AC 220V±5%, 50Hz External Dimensions 600mm × 400mm × 410mm (Length × Width × Height) Host Net Weight 50kg

ingenuity quality

Factory direct sales

Support customization

a lot of in stock

Quality Assurance

complete specifications

After-sales worry-free

Factory Scene

Production Scenarios

LHCQ-533A pneumatic screen

Still decided? Get the samples first,Contact us!

Product classification

Shipping video

Shipping photos

Shipping scenarios

Shipping

INQUIRY

Note: Please leave your contact number or E-mail address, our professionals will contact you as soon as possible!

Related Products

LHCL-0985E Adhesion Layer Tensile Tester

LHLS-0985A Bonding Layer Dedicated Pull-out Tester

LHLDY-0362 Coarse Aggregate Flow Time Tester

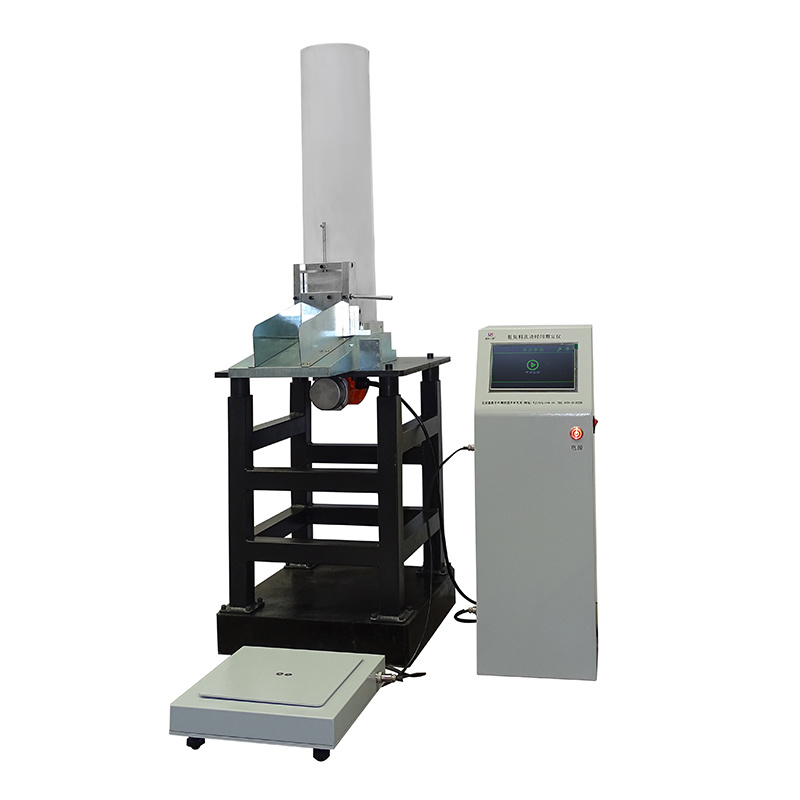

LHSL-326E Expansion Joint Rubber Seal Strip Clamping Performance Testing Machine