Share

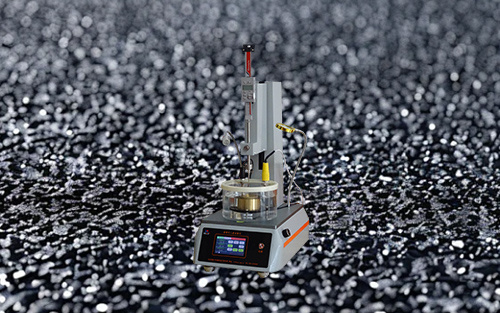

Asphalt Mixture Rotary Compactor

Still decided? Get the samples first,Contact us!

Product classification

Keywords

- Description

-

Applications

In the laboratory, simulating the volumetric properties and engineering attributes of actual pavement materials, using a kneading method under three main technical conditions: constant vertical pressure, constant compaction angle, and specified compaction speed. The specimen undergoes uniform circular periodic rotation at an eccentric angle. After constant-pressure compaction, the eccentric angle is removed, and constant-pressure rotation is performed for leveling, completing the experimental process of preparing cylindrical specimens of hot-mix asphalt mixture.

The compaction angle specified in this standard refers to the effective internal angle during the test with the rotary compaction instrument.

Structure

The rotary compaction instrument mainly consists of a reaction frame, a loading device, a rotating base, a force measuring device, a displacement measuring device, a computer control system, and a mold. A structural diagram of a rotary compaction instrument that uses electronic-mechanical integration technology is shown.

1. Applications: Forming specimens for testing the physical and mechanical properties of asphalt mixtures.

2. Working Conditions: Laboratory working conditions

Technical Parameters

Meets the requirements of JTG E20-2011 for highway engineering asphalt and asphalt mixture test methods in measuring compaction pressure, rotation times, and specimen height.

Imported PLC control, computer control operation, real-time display of various parameters and curves.

Rotation Angle: 0~20° ±0.02° adjustable. (The angle is adjusted before leaving the factory. It is not recommended that customers adjust it themselves. If you need to adjust it, please contact the manufacturer.)

Times

4. Rotary Compaction Angle Accuracy: Less than 0.01°

5Displacement Range:0~250mm

6. Power Supply Voltage: 380V

7. Power: 1.1KW

8. Ambient Temperature:≦85%

9Pneumatic type can make diameter 100 or 150 specimens

10. Dimensions:95×73×193cm

11.Accessories: ConfigurationΦ150mm mold

12. Software: Complete supporting software

ingenuity quality

Factory direct sales

Support customization

a lot of in stock

Quality Assurance

complete specifications

After-sales worry-free

Factory Scene

Production Scenarios

Asphalt Mixture Rotary Compactor

Still decided? Get the samples first,Contact us!

Product classification

Shipping video

Shipping photos

Shipping scenarios

Shipping

INQUIRY

Note: Please leave your contact number or E-mail address, our professionals will contact you as soon as possible!

Related Products

RT-CM Type Asphalt Mixture Coring Machine

LHHD-I type pavement cross-section ruler

LHZJ-0985D Shear Strength Tester for Bonding Layer

LHGL-740 Road-use Heating Type Sealant Tensile Tester