Share

Double-end surface grinder

Still decided? Get the samples first,Contact us!

Product classification

Keywords

- Description

-

Overview

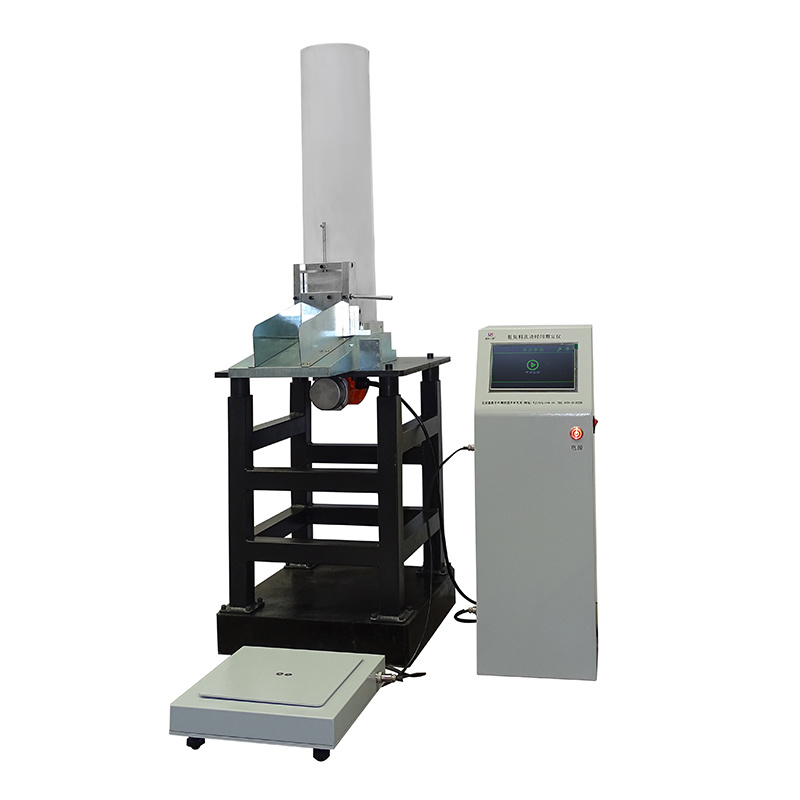

Double-end surface grinding machine is an essential main equipment for preparing standard samples for mechanical testing of various rocks, ores, concrete, and other non-metallic solids. This machine, when used in conjunction with the core drilling machine and stone cutting machine produced by our factory, can process high-precision cubic or cylindrical test specimens as you require. It is widely used in colleges and universities, water conservancy and hydropower, geology and mineral resources, transportation, construction, and other departments. The machine consists of a base, worktable, grinding power head, variable speed transmission system, and electrical control device. The entire machine is easy to operate, with automatic feeding and stable performance.

Fully complies with the Ministry of Transport (JTG E20-2011) standard.

Technical Parameters

1. Voltage: 380V, 50Hz Input: three-phase three live wires and one neutral wire

2. Grinding moving head power: 1.1KW × 2 units 1400 rpm

3. Worktable motor power: 50W 25 rpm

4. Grinding wheel diameter: Ø180~Ø200mm

5. Specimen sizes that can be ground:

Cube, cylinder: 50×50×50mm

150×150×150mm

100×100×100mm

6. Standard accuracy:

A. Flatness: tolerance ±0.05mm within 50mm range

B. Surface finish (according to mechanical processing roughness standard): Ra3.2

7. Automatic grinding feed amount: adjustable from 0.01 to 0.5mm

8. Overall dimensions: length 1180 × width 1050 × height 1080mm

9. Weight: 183kg

ingenuity quality

Factory direct sales

Support customization

a lot of in stock

Quality Assurance

complete specifications

After-sales worry-free

Factory Scene

Production Scenarios

Double-end surface grinder

Still decided? Get the samples first,Contact us!

Product classification

Shipping video

Shipping photos

Shipping scenarios

Shipping

INQUIRY

Note: Please leave your contact number or E-mail address, our professionals will contact you as soon as possible!

Related Products

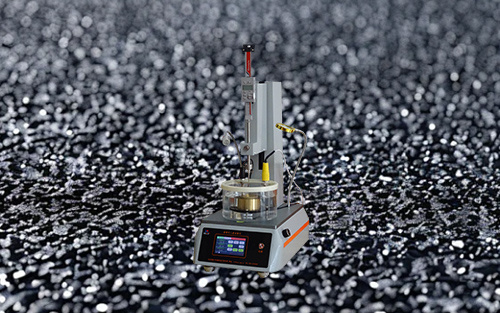

LHCL-0985E Adhesion Layer Tensile Tester

LHLS-0985A Bonding Layer Dedicated Pull-out Tester

LHLDY-0362 Coarse Aggregate Flow Time Tester

LHSL-326E Expansion Joint Rubber Seal Strip Clamping Performance Testing Machine