Share

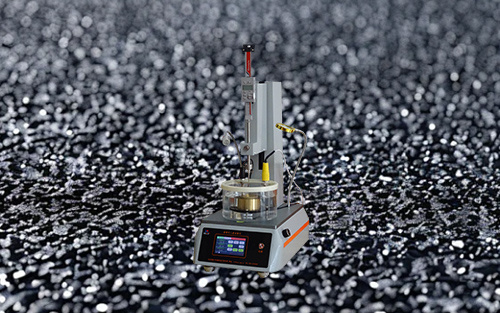

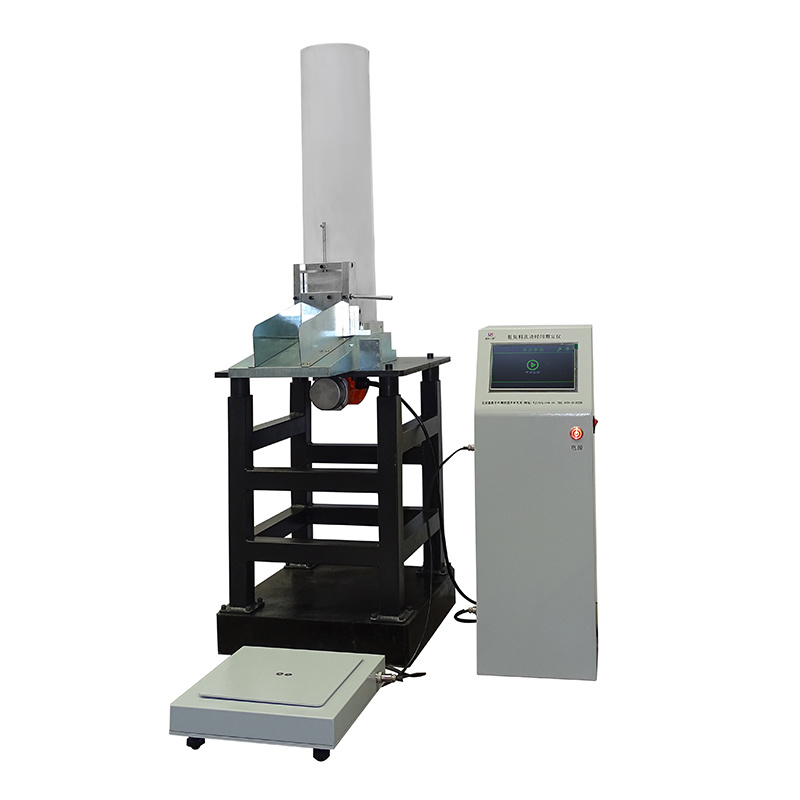

Multifunctional Pavement Material Strength Testing Instrument

Still decided? Get the samples first,Contact us!

Product classification

Keywords

- Description

-

Overview

This machine integrates the research and development of various compressive strength constant pressure testing instruments according to relevant standards. , The instrument parameters comply with the latest standard specifications. It integrates soil bearing ratio ( CBR ) tests, Marshall stability tests, unconfined compressive strength tests, mortar cube compressive strength tests, and customizable compressive constant pressure tests. (Users can expand to various compressive constant pressure tests) It uses a servo motor drive, a highly efficient self-developed reduction device (patented product) combined with a high-precision ball screw. It represents a qualitative improvement over older models of the same type.

Complies with JTG3430-2020 "Specifications for Highway Geotechnical Testing", JTG E51-2009 << Specifications for Testing of Inorganic Binder Stabilized Materials in Highway Engineering ">> GB/T50123-2019 Relevant tests in the "Standards for Geotechnical Testing Methods".

Pavement Material Strength Comprehensive Tester Includes the main unit, force measuring device, and related accessories for force measurement. Meanwhile, the main unit of this testing instrument requires only minor modifications and the addition of relevant accessories to complete various tests requiring vertical load application.

Technical Features

- Loading speed: 0-80mm/min Rate can be set arbitrarily, with automatic rate switching function to improve work efficiency.

- Operational noise is negligible; no noise at low speed.

- Uses two dial gauges for displacement monitoring, with touchscreen synchronized displacement display and related dial gauge operations.

- Multiple force sensors can be configured according to user needs. Supports up to 5 types of force sensor parameter settings and calibration.

- The appearance has undergone bold innovation, conforming to ergonomic design, using a 10 -inch touchscreen as the human-machine interface, simple operation, and convenient settings. Combined with mechanical buttons, - it simplifies complicated test procedures as much as possible.

The operating speed serves as the manual operation speed or the starting speed for some tests supporting speed switching. 0-80mm/min It is recommended to set within 0-60mm/min . Excessively high speeds may cause motor stall and driver alarms (the motor has a built-in protection mechanism - which does not damage the equipment).

Since this machine supports multiple range force sensors, it is necessary to select a matching force sensor according to test requirements, each range of force sensor has corresponding calibration values. Incorrect selection results in incorrect force values. 。

Ensure that the force sensor used matches the configured force sensor range; otherwise, over-range may cause sensor damage.

The maximum force value should be set within the sensor range. After reaching the maximum force, the test automatically stops and cannot increase further. Only decreasing the force value is allowed.

- Loading speed: 0-80mm/min Rate can be set arbitrarily, with automatic rate switching function to improve work efficiency.

ingenuity quality

Factory direct sales

Support customization

a lot of in stock

Quality Assurance

complete specifications

After-sales worry-free

Factory Scene

Production Scenarios

Multifunctional Pavement Material Strength Testing Instrument

Still decided? Get the samples first,Contact us!

Product classification

Shipping video

Shipping photos

Shipping scenarios

Shipping

INQUIRY

Note: Please leave your contact number or E-mail address, our professionals will contact you as soon as possible!

Related Products

LHCL-0985E Adhesion Layer Tensile Tester

LHLS-0985A Bonding Layer Dedicated Pull-out Tester

LHLDY-0362 Coarse Aggregate Flow Time Tester

LHSL-326E Expansion Joint Rubber Seal Strip Clamping Performance Testing Machine